All you need for your business regarding hydraulic hose crimping machines are found in KDM. Let KDM be your partner to grow your business! KDM can produce custom hydraulic hose crimping machine based on your own requirements.

- 100% inspection guaranteed

- Fully customized hydraulic hose crimping machine

- Hundreds of models available

- Very competitive rates

KDM Hydraulic Hose Crimping Machine

KDM is your hydraulic hose crimping machine specialist in China. As a leading hydraulic hose crimping machine manufacturer and supplier, we possess thousands of standard hydraulic hose crimping machine that comes in multiple sizes and designs. Below are the top-rated hydraulic hose crimping machines we offer.

KDM Hydraulic Hose Crimping Machine

As a leading manufacturer in China, we choose the best quality raw materials for these machines to satisfy your needs.

This type of machine is specially designed for extreme working conditions like tropical sites or mines. Available at competitive rates.

KDM is a professional hydraulic hose press crimping machine manufacturer in China. Here in KDM, we welcome old and new clients.

KDM offers a wide range of 10-87mm hydraulic hose crimping machines for your business. We offer OEM and ODM services to support your business.

This kind of machine is designed to make rubber products. Also, it can be used as a cold press machine when don’t heat it.

Applicable for all kinds of mechanical low & high-pressure oil pipes, water pipes, gas pipes, automotive conditioning pipes, cables, and more.

We have a wide range of different models for hydraulic hose crimping machines to support your business. We welcome old and new clients.

A fully Automatic Hydraulic Hose Crimping Machine is suitable for all tubes, wires, belts, sheets, and films. You can avail of this machine at competitive prices.

We choose the best quality raw materials for a high-pressure hose crimping machine. We do customize high-pressure hose crimping machines based on your requirements.

We offer a wide range of custom and standard portable hydraulic hose crimping machines to fully support your business.

For any particular application, KDM offers a wide range of industrial hydraulic hose crimping machines in many different sizes, designs, and specifications.

All of our Hydraulic Oil Hose Crimping Machine is guaranteed high-quality. You can avail of this machine at affordable prices.

Why KDM Hydraulic Hose Crimping Machine

You can avail of our KDM hydraulic hose crimping machine in various models, designs, and sizes or any specifications based on your requests. KDM has a professional R&D team to manufacture the custom hydraulic hose crimping machine you need.

We have a lot of available hydraulic hose crimping machines that can save your time and cost. KDM offers OEM/ODM services and CAD Drawing according to your sample design.

Popular KDM Sheet and Pipe Processing Machines for Your Business

KDM -Your Professional Hydraulic Hose Crimping Machine Manufacturer

- Factory

KDM Hydraulic Hose Crimping Machine

If you’re looking for an excellent hydraulic hose crimping machine manufacturer in China, KDM can do the job. KDM is very competent in manufacturing and supplying thousands of hydraulic hose crimping machines that meet your requirements.

KDM hydraulic hose crimping machine is popular in many industries around the world such as heavy machinery, hydraulic hoses, construction equipment, automotive components, mining, marine, railroad, industrial hoses and tube, wire, pipe, cable industry, etc.

You can use KDM hydraulic hose crimping machine for crimping processing. KDM hydraulic hose crimping machine is suitable for crimping steel pipes, especially irregular shape pipes and large pipes. Our hydraulic hose crimping machine is easy to use, guaranteed long life and reliability.

Whether you need a hydraulic hose crimping machine for your business or personal use, KDM has a superb option for you. Our hydraulic hose crimping machine is accessible in different models, designs, and colors.

In China, KDM is popular for being a dedicated, reliable, and outstanding provider and manufacturer of custom and standard hydraulic hose crimping machines. KDM hydraulic hose crimping machine and other pipe machine products are highly appreciated by many customers in many countries like Africa, Mexico, America, etc.

KDM is a manufacturer and worldwide provider of custom, standard, and OEM hydraulic hose crimping machines. Our range of hydraulic hose crimping machines allows us to complete your needs.

Whether you`re a distributor, supplier, or custom factory, KDM really helps you boom your business. We are your one-stop hydraulic hose crimping machine solution. All your pipe machine necessities are all here!

Contact us now for more details!

Hydraulic Hose Crimping Machine- The Ultimate FAQ Guide

If you have any question on hydraulic hose crimping machine, you will find the answer right here.

It is because this guide covers all information you’re looking or about hydraulic hose crimping machine.

So, keep reading to learn more.

- What Is Hydraulic Hose Crimping Machine?

- What Are The Types Of Hydraulic Hose Crimping Machines?

- How Does Hydraulic Hose Crimpling Machine Work?

- When Should You Use A Low-Pressure Hydraulic Hose Crimping Machine?

- When Should You Use A High-Pressure Hydraulic Hose Crimping Machine?

- What Does A Vertical Hydraulic Hose Crimping Machine Do?

- What Does A Horizontal Hydraulic Hose Crimping Machine Do?

- How Should You Use A Hydraulic Hose Crimping Machine?

- What Is The Best Hydraulic Hose Crimper?

- What Is The Price Of A Hydraulic Hose Crimping Machine?

- How Much Pressure Does A Hydraulic Hose Crimping Machine Exert?

- How Do You Minimize Wear And Tear On Your Hydraulic Hose Crimper?

- What Are The Safety Tips For Using A Hydraulic Hose Crimping Machine?

- Why Are Hydraulic Hose Crimping Machines So Popular?

- What Are Some Of The Hydraulic Hose Crimping Machine Certifications?

- What Are The Dimensions Of A Hydraulic Hose Crimping Machine?

- Do I Need Any Additional Hydraulic Hose Crimping Accessories?

- What Is Hydraulic Hose Crimp Dies?

- What Size Of Hydraulic Hose Crimp Dies Should I Use?

- How Do You Set Up A Hydraulic Hose Crimping Machine?

- What Should You Do If The Fan Hydraulic Hose Crimping Machine Is Rotating In The Anti-Clockwise Direction?

- How Durable Is A Hydraulic Hose Crimping Machine?

- What Do I Do If The Hose Crimping Machine Fails To Turn On?

- Why Is A Hydraulic Hose Crimper Better Than A Traditional Crimper?

- Is A Hydraulic Hose Crimping Machine Economical To Operate?

- When Do I Replace The Oil In My Hydraulic Hose Crimping Machine?

- What Characterizes A Good Hose Crimper?

- Are Linked Dies Beneficial?

- How Often Should I Clean The Filter On Hydraulic Hose Crimping Machine?

What Is Hydraulic Hose Crimping Machine?

Hydraulic hose crimping machines are tools that you use to join malleable metallic fittings to sections of flexible hose tubing.

What Are The Types Of Hydraulic Hose Crimping Machines?

You can find two types of hydraulic hose crimping machines. They are either classified as automatic and manual.

Automatic Hose Crimping Machine

Manual Hose Crimping Machine

Automatic crimping machines are controlled by an electric system while the manual ones are controlled by a manual control valve.

Automatic and manual crimping machines can also be classified either vertical or horizontal. They can either be high pressure or low pressure.

Horizontal hose crimping machines are used for two-way bends, which is to the right and to the left. They offer you great flexibility.

Vertical hose crimping machines gives you the ability to manually adjust crimping angles. This is done by adjusting the die holder.

High pressure hose crimping machines are used to crimp large and dense metallic hoses. They are capable of channeling a lot of pressure through the hydraulic fluid, hence have great efficiency.

Low pressure hoses on the other hand, are ideal for smaller hoses. They operate using comparatively lower Psi.

How Does Hydraulic Hose Crimpling Machine Work?

The working mechanism of a hydraulic hose crimping machine are fairly complex.

A pressure sleeve is turned by a cylinder plunger, while the pressure head is inserted in the main tube. The core is them inserted in the spring indenter, through the focal opening.

You use the control panel to move the plunger.

The spring indenter is consequently pushed through the focal opening.

The hydraulic fluid is pushed through the system, converted to hydraulic energy then back to mechanical energy.

The mechanical energy acts on the metallic hose, bending it on the opposite direction of the pressure sleeve.

When Should You Use A Low-Pressure Hydraulic Hose Crimping Machine?

You should use low pressure hydraulic hose crimping machine when dealing with small hoses. They are also ideal for hoses that have a regular shape.

Small Regular Shaped Pipes

Examples of such hoses are, welding hoses, diesel hoses water hoses, air conditioner hoses and brake hoses.

When Should You Use A High-Pressure Hydraulic Hose Crimping Machine?

You should use a high-pressure hydraulic hose crimping machine when crimping hoses are super large.

They are perfect for irregular shapes or pipes that are made out of steel.

Large Pipe

They are mostly used in vehicle and railway engineering as there is usage of large pipes.

What Does A Vertical Hydraulic Hose Crimping Machine Do?

You use a vertical hydraulic hose crimping machine eliminates the circular degree problem as it has a modified die holder.

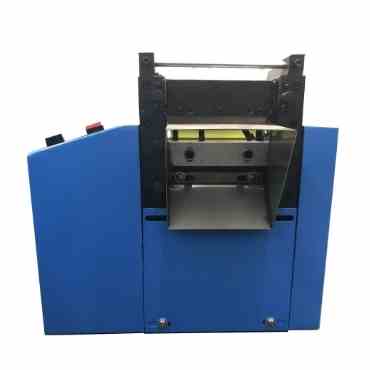

Vertical Hydraulic Hose Crimping Machine

Vertical hydraulic hose crimping machines are preferred by most technicians as their operating systems are advanced.

What Does A Horizontal Hydraulic Hose Crimping Machine Do?

If you want to crimp two-way bends, a horizontal hydraulic hose crimping machine would be ideal.

Horizontal Hydraulic Hose Crimping

Due to this feature, high pressure horizontal hydraulic hose crimping machines are preferred in vehicle and railway engineering fields.

How Should You Use A Hydraulic Hose Crimping Machine?

You should measure and cut the length of the hose to be used ensuring the edge is smooth.

Mark the depth of the hose to be inserted then select the crimp diameter.

Proceed to select the appropriate crimp die for the hose.

You should then place the hose in the machine and the compression ring above the die. Turn on the machine.

The collar will be pushed through the machine. This occurs automatically. In the process, the die will be compressed. You should wait until the collar becomes visible under the crimp die.

Once you see the collar, the crimping process is complete. Ensure that you turn off the machine after crimping.

What Is The Best Hydraulic Hose Crimper?

The best hydraulic hose crimping machines are the modern hydraulic machines.

KDM hydraulic Hose Crimp

Such include the vertical hydraulic hose crimping machine which tend to have a ton of benefits.

You will find them long lasting, accurate, and able to withstand daily work, manageable and user friendly.

What Is The Price Of A Hydraulic Hose Crimping Machine?

Prices of hydraulic hose crimping machines vary due to various factors.

They include, the type, quality, manufacturer, production capacity among other factors.

You will find that prices range from $500 to $6000 depending on what kind of machine you wish to purchase.

How Much Pressure Does A Hydraulic Hose Crimping Machine Exert?

Pressure exerted by a hose crimping machines depends on the type of machine you are using.

High pressure machines tend to have a high pressure compared to low pressure hydraulic hose crimping machines.

However, there is a standard maximum pressure set by the ISO standard 18752. The pressure standard is set depending on your machine’s grade.

How Do You Minimize Wear And Tear On Your Hydraulic Hose Crimper?

You can do this by frequently inspecting the crimping machine. Following the manufacturer’s guidelines also helps in prolonging your machine’s life.

Be sure to get rid of cracked hoses that rub against their clamps.

Determine the proper insertion depth and hose size before inserting the hose to avoid damage. Ensure you clean the machine after usage.

What Are The Safety Tips For Using A Hydraulic Hose Crimping Machine?

You should put on safety gear such as; gloves, ear protectors and goggles when operating the machine.

Basic safety equipment for handling Hydraulic Hose Crimping Machines

Make sure the dies are suitable for the crimp and don’t insert them when power is on.

Ensure your work area is clean and the work surface is stable. Examine the installations carefully before turning on the machine.

Why Are Hydraulic Hose Crimping Machines So Popular?

Their durability is high due to the enclosed water tank which makes it dust free hence low production cost.

They are made out of metal that is resilient to temperature and light. They are affordable and time saving.

What Are Some Of The Hydraulic Hose Crimping Machine Certifications?

ISO standard 18752 indicates that all hydraulic designers must meet the maximum pressure and performance requirements.

Official ISO 18752 certifications

What Are The Dimensions Of A Hydraulic Hose Crimping Machine?

Dimensions of a hydraulic hose crimping machine are measured by multiplication of its length breadth and width.

Dimension is always in millimeters SI unit symbol (mm). Example a hydraulic hose crimping machine dimension might be 450 by 650 by 750.

Do I Need Any Additional Hydraulic Hose Crimping Accessories?

You might need:

- Hydraulic lubricant to lubricate the hose before insertion

- Hydraulic cylinder which aids in installing fittings on large hoses

- Crimper lubrication for cleaning the crimper

- Calipers for measuring hoses before and after cutting.

Hydraulic cylinders

Hydraulic Lubricant

What Is Hydraulic Hose Crimp Dies?

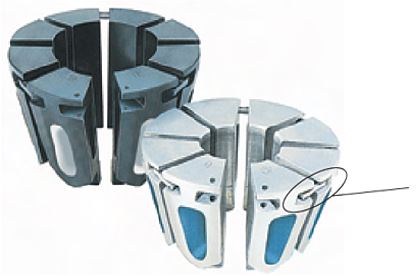

This is a part of the hydraulic hose crimp that aid you in forming a uniform crimp. The crimp dies have parker lines that facilitate proper fitting.

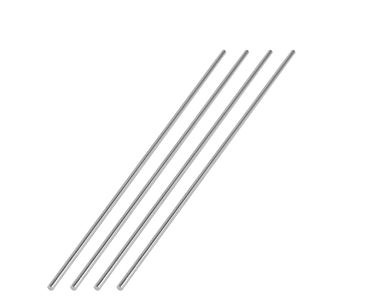

Hydraulic Hose Crimping machine die

Crimp dies are unitized so as to make them manageable.

What Size Of Hydraulic Hose Crimp Dies Should I Use?

The sizes of hose fittings and dies series you should use are indicated on top of the crimp dies. This makes it easier for you to select the most appropriate crimps.

Die Fittings for a Hydraulic Hose Crimping Machine

How Do You Set Up A Hydraulic Hose Crimping Machine?

You need to open the panel board and add oil to the tank.

Do not fill the tank. Carefully place the crimping head on the main body and mount it using the provided bolts.

You should then fit the hydraulic hoses to the cylinder.

The hoses connect the body and the crimping head.

Attach the micrometre to the crimping head and bolt it down firmly. Connect the micrometre to the panel. Plug in the machine and confirm that the fan rotates in a clockwise manner.

What Should You Do If The Fan Hydraulic Hose Crimping Machine Is Rotating In The Anti-Clockwise Direction?

It is relatively easy to fix this problem. You need to interchange the live and neutral connections that run into the power supply.

Live, Earth and Neutral connections

How Durable Is A Hydraulic Hose Crimping Machine?

You can’t get a definitive answer to this question, as it depends on a myriad of factors.

The main factor is maintenance. If you maintain the machine frequently, it will last longer.

The intensity of usage plays a pivotal role in the lifespan of a machine.

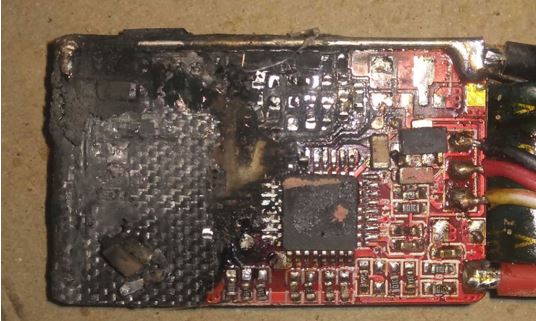

If the workload is often intensive, the dies will develop cracks. It also causes a lot of wear and tears on the electrical components.

Well maintained die

What Do I Do If The Hose Crimping Machine Fails To Turn On?

You should check whether or not the machine is plugged into a power source. Proceed to inspect the connection.

Your machine may also fail to turn on if the fuse is blown. Ensure that you have enough oil in the tank.

Damaged hose crimping connector

A dirty valve may also cause your die to stop working, so ensure that you clean them regularly.

Why Is A Hydraulic Hose Crimper Better Than A Traditional Crimper?

You will note that a hydraulic hose crimper uses fewer molds, and is, therefore, cheaper to run. It also requires far lesser engine brackets.

This makes it quite easy to maintain.

Hose crimper Mounting Brackets

Modern hose crimping machines require no more than 10 radiator brackets. Traditional crimpers on the other hand need at least 17.

Is A Hydraulic Hose Crimping Machine Economical To Operate?

If you decide to purchase a hose crimping machine, you will save on operating costs.

Compared to traditional crimping machines, a hydraulic hose crimper has a very low maintenance cost.

With torque optimization, they can handle heavy workloads, without drawing a lot of electricity. This property makes them budget-friendly for your business.

When Do I Replace The Oil In My Hydraulic Hose Crimping Machine?

You should look to replace the oil in the machine if the level reduces to a point that would necessitate it.

Clear and dirty oil comparison

The colour of the oil also tells you when it is appropriate to replace it. Black and discoloured oil indicate that the oil is oxidized and must be replaced as soon as possible.

What Characterizes A Good Hose Crimper?

You should look for various features, some of which include:

- The overall design of the die

- If the machine is durable

- The electrical consumption.

Are Linked Dies Beneficial?

Linked dies are quite useful, as they prevent you from mismatching. Linked dies are also very easy to install as they fit into the body quite easily. The linking improves their structural integrity as well as their stress strength.

Linked Aluminum Dies

How Often Should I Clean The Filter On Hydraulic Hose Crimping Machine?

A filter should be cleaned or changed after no more than 50 working cycles. Failure to clean the filter will result in dirt accumulating on the oil.

This means you have to spend a lot of money changing the oil.

Clean and dirty filter comparison

For all your hydraulic hose crimping machine, KDMSteel offers perfect solutions for all your needs.

Contact us now for all your hydraulic hose crimping machine needs.